Project Overview

The electrode coating process forms the active layers of lithium-ion batteries by applying precisely metered slurries to metal foils — typically cathode material on aluminum and anode material on copper — using roll-to-roll equipment. The coated foils are then dried and sent downstream for pressing and slitting.

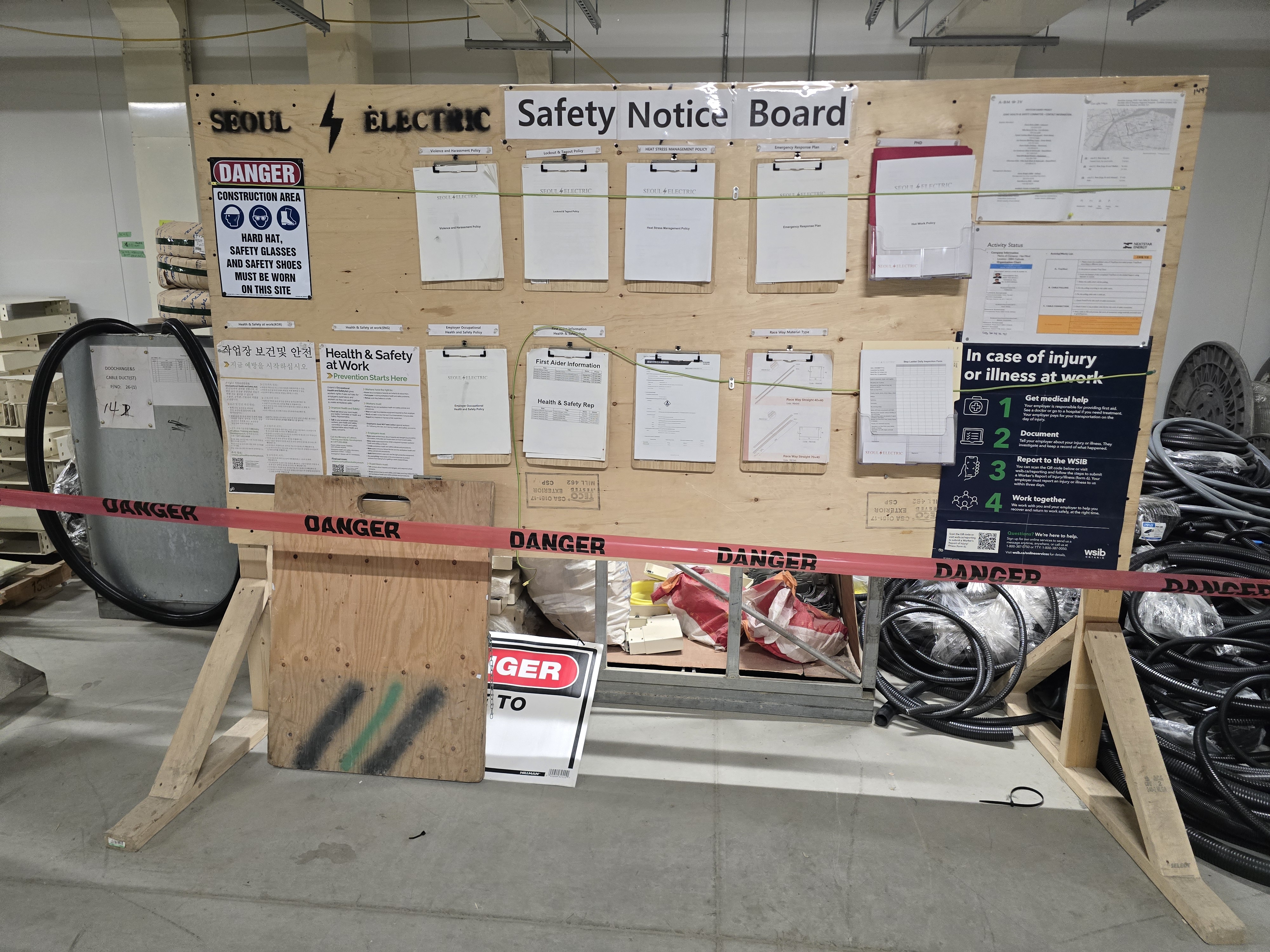

This project delivers the electrical infrastructure and integration for both cathode coating and anode coating machines, including power distribution, controls, and field terminations to support safe, reliable production.

Project Gallery

Project images shown; sensitive details not displayed.

Scope of Work

- Coating Machines: Electrical installation for cathode and anode coating equipment (roll-to-roll, slot-die capable).

- Cable Trays & Raceway: Supply and install trays, supports, and raceway systems; layout, mounting, and bonding.

- Cable Pulling & Terminations: Feeder and control cable pulls, labeling, ferruling, and verified terminations.

- Control Panels: Panel installation, I/O marshaling, interlocks, and PLC/aux wiring to OEM specifications.

- Procurement: Sourcing and ordering required control panels and electrical components per approved submittals.

- Lighting & Aux Power: Task/area lighting, receptacles, and auxiliary services around the coating line.

- Commissioning & Testing: Pre-start checks, loop/point verification, megger and torque logs, and on-site support during line commissioning.

- Documentation & Compliance: ESA/OESC inspection support, as-built updates, and turnover packages.

Outcomes

- Safe, reliable power and controls for cathode/anode coating lines.

- Verified terminations and documented test results for commissioning.

- Clean, maintainable installs aligned with long-term operations.